In the virus prevention period, the lacking of medical supplies and limits of disposable masks are the critical issues in many regions, it means support to mask production capabilities are the main solution for the issues. In response, Rhein-Koester started the R&D of mask manufacturing machine on the first day of work resumption, and devoting to support manufactures to improve their production capabilities.

In the R&D process, we adapt the most advanced ‘Digital twin virtual simulation technology’ to short the development period of production line. Within 30 days, the solution of new ‘automation mask production line’ are well developed, and we introduced technical supports in along with delivery of solutions. Based on the achievements, Rhein-Koester provides medical supply companies with a comprehensive solution that supports them to produce in a higher efficiency.

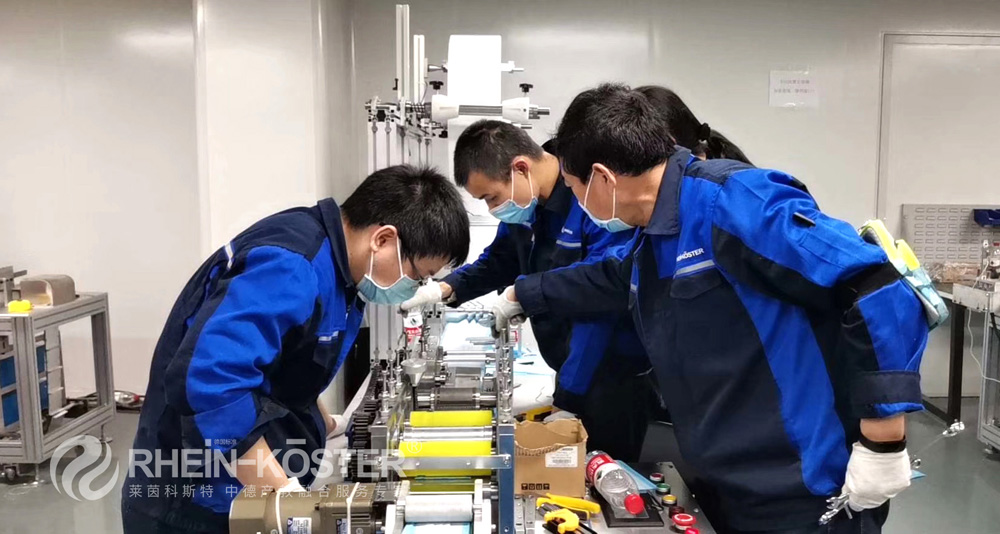

Besides the R&D, our industrial technical support for enterprises are the core business. “In recent, a company in Changsha, Hunan, purchased 30 mask production machines, however, due to the after-sale service of machine vendors are not timely offered and which caused idle of machines. In the case, the corporate manager urgently contacted Rhein-Koester for technical supports; after our technical advises and on-site adjustment, the production capabilities are significantly increased from 10 thousand/day to 100 thousand/day”, declared by Yi Weibiao, the Project Manager of Rhein-Koester (Zhuzhou) Co.,Ltd.

For corporate development under ‘2019-nCoV’, only technical advantages are not sufficient for offering of qualified industrial services. Mr Cui Zhi, the GM of Rhein-Koester claimed that we have integrated our technical advantages&project experience with talent development solution which are well developed by Sino-German experts team. Each of our developed intelligent manufacturing practical training equipments are equipped with completed ‘Online+Offline’ course system, which truly realized the perfect integration between talent development and the most advanced technologies in field of intelligent manufacturing.

For corporate transformation & upgrade and the need of talent, Rhein-Koester launched ‘German standardized & customized talent development class’, ‘Medium-long training class’, ‘Short-term training class’ and ‘online training class’ to support talent development, and further provide hundreds of enterprises with ‘Intelligent and advanced’ talent development services.

In the period of ‘2019-nCoV’, we launched plenty of online public classes based on corporate needs, and help enterprises to accelerate their talent development progress. In the case of ‘digital-twin’ class which takes mask production machine as an instance, it is not only a class to interpret concepts of talent development in field of industrial digital twin, it simultaneously allows engineers have an in-depth understanding about practical application of digital technologies; introduced by Mr Wang Honglei, the director of Rhein-Koester Education department.

Rhein-Koester is a group which integrates Sino-German manufacturing and education, the company dedicated to construct a ‘Full Industrial Chain’ platform which integrates Manufacturing, Education, Research, Application and Service in digital economy and intelligent manufacturing. Based on our international advanced technology and training system, we have confidence to build ‘Online+Offline’ double engines to support development of manufacturing enterprises in the current critical situation.