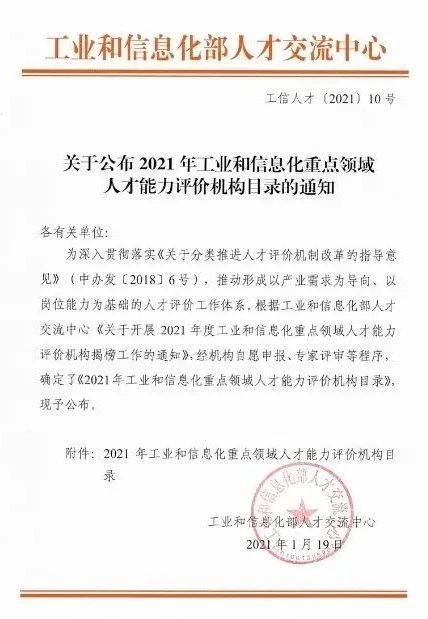

For implementation of ‘Instructions about promotes and revolute talent assessment system’, and establish a demand-oriented, position abilities requirement based talent assessment system. On 19th of January, 2021, Ministry of Industry and Information Technology of the PRC issued ‘List of 2021th Talent Assessment Institutions’. Through the process of application and assessment, Rhein-Koester has been again selected as talent ability assessment institution, in additional to industrial internet, the assessment works will be carried out in digital twin technology and robots.

Rhein-Koester is committed to establish the ecological loop of ‘Industry supports education — Education develop talents — Talents support industries’, and develop an innovative model which integrates education and industry. In nationwide, Rhein-Koester owns multiple ‘College+Institute+Base+Park’ platforms. To be chosen as one of the talent assessment institution means social recognition and acceptance.

Integrates international senior resources, construct new generation applied platform of industrial internet technology

Rhein-Koester is one of the units for talent ability promotion in industrial internet industry, which authorized by the ministry of industry and information technology of the PRC. Rhein-Koester has built long-term partnership with Bielefeld FH: Fachhochschule Bielefeld, Siemens group, SAP, Steinbeis, Technische Hochschule Deggendorf, Fraunhofer association. The company is committed to develop core technologies of digital factory, and industrial IoT PAAS cloud services; Rhein-Koester’s self-developed industrial internet platform would not only satisfy prototype development of products in industrial internet, commercialization of products, operation and management; but also could develop applied talents based on the platform resources.

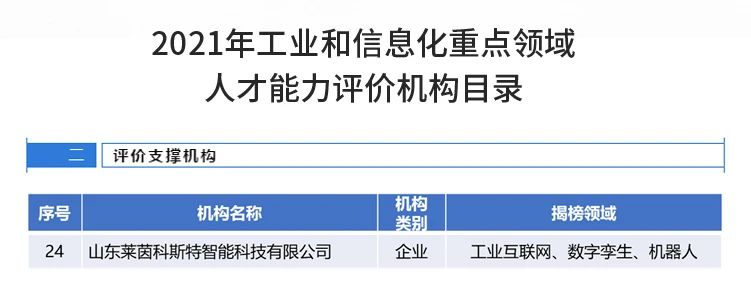

Focusing on digital twin technology, integrates digital technologies and manufacturing process

The experts team from Rhein-Koester developed program to simulate production line, the program would monitor and manage production line. Rhein-Koester digital-twin platform adapts design of ‘Virtually Reflection on Real Manufacturing’, and integrates intelligent manufacturing practical training facilities with digital software system, which enable trainees to carry out practical trainings on virtual platform. The platform truly realized the integration between virtual, reality, learning and trainings. The company is transforming ‘industry 4.0’ technologies into an innovative model which better suitable for ‘Made in China 2025’, and lastly develop senior talents who is proficiency in digital control technology and operation of advanced manufacturing systems.

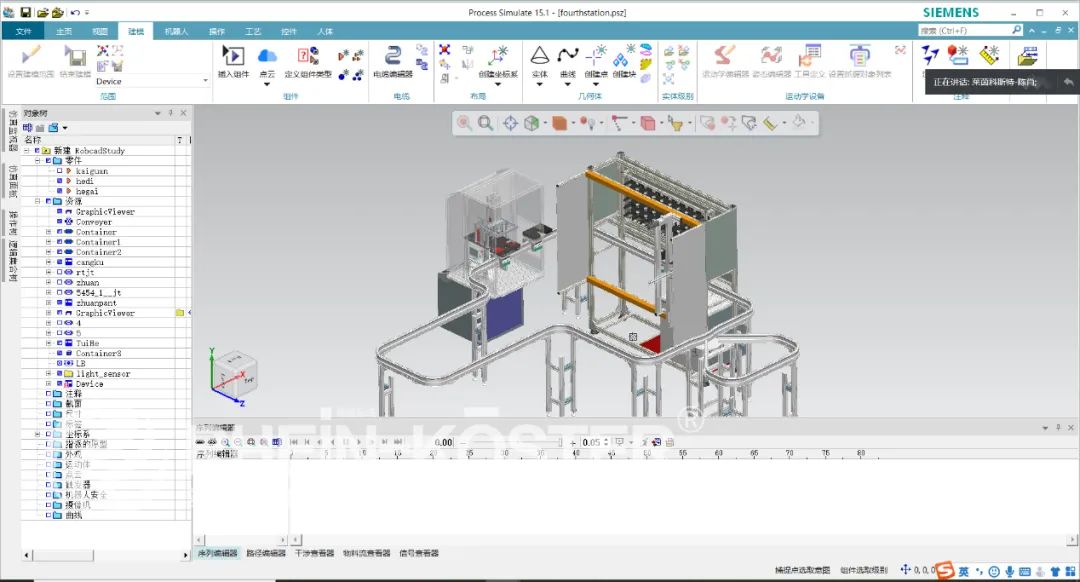

Develop Platform of Intelligent Collaborative Platform Technologies, Construct Industrial Ecosystem

Rhein-Koester, Siemens, and Zibo High-tech zone administration committee signed agreement for construction of ‘Sino-German Intelligent Collaborative Robots R&D Center’, the center (public technology platform) consists of New generation collaborative robots technology, intelligent robot flexible manufacturing, robots online manufacturing and sharing manufacturing, lightweight connected data solution, industrial internet and online vocational education platform of intelligent robots. The platform involves industrial internet, intelligent collaborative robots technologies, technical standards development and incubation. The platform would work with Siemens and jointly promotes the integration between industrial robots technologies, industrial internet and artificial intelligent, and lastly develop an industrial cluster of robots and eco-system of robots industries.

Based on the Sino-German Intelligent Manufacturing Industry-Education Demonstration base, Rhein-Koester would exert advantages of industrial internet technology, digital twin technology, industrial robot technology and trainings of intelligent manufacturing to design training systems, design teaching plan, develop syllabus and training textbooks for ‘dual-system’, online training platform, practical training base under German standards, digital twin VR system and other training tools, the courses cover industrial automation, and subjects for the main technologies and products in field of intelligent manufacturing. The course are available to be customized for new technicians and on duty engineers, and ensure the successful completion of talent assessment.